Three creative projects aimed at improving the safety and mobility of people with disabilities appeared at the College of Engineering and Computational Sciences Spring 2014 Trade Fair. The two we detail below received special recognition.

The brake system and seat back on this fourcross bike received design improvements that increased rider control and safety (photo shows bike prior to modifications). The CSM FourCross team included Clayton Boatwright ’14, Emily Hixon, Abigail Krycho, Hannah Margheim ’14, William Pietra ’14, Jacqueline Stabell ’14 and Brian Stack ’14. Photo: Joel Bach, Thin Air Images

Better Brakes, Seat for Four-wheel Mountain Bikes

Mechanical Engineering Professor Joel Bach was at the No Barriers Summit in Telluride, Colo., last summer when he heard about some problems faced by Crested Butte’s Adaptive Sports Center in providing downhill mountain bikes that were safe and efficient for quadriplegic riders whose core and grip strength is compromised. Bach brought this information back to Mines, and the senior design team CSM FourCross was formed.

Video: Riding down the center�s trail in August 2013

The team of seven focused on improving the bike’s braking system and seat safety, receiving advice and guidance from their advisor, Paul Panozzo MS ’97, as well as Bach and Assistant Professor of Mechanical Engineering Anne Silverman.

The braking system in the original design consisted of traditional bike brakes reversed so they face the rider. With hands strapped or taped to the brake levers, riders would brake by pushing or leaning forward. However, unintentional braking was hard to avoid: firstly, riders tended to sit leaning forward, resulting in some forward pressure on the brakes; secondly, steering required some forward pressure.

In CSM FourCross’s design, small pedals are attached to motorcycle throttle-style twist grips connected to the brake levers. With hands strapped to the twist grips and forearms resting on the pedals, riders brake either by rotating the grip through wrist action, or by leaning forward and lowering their elbows. Since the system is spring-loaded, riders are able to rest their hands on the pedals and steer without braking.

Video: How CSM FourCross�s new brake design work

For the new seat back, the goal was to prevent hyperextension of a rider’s back during a crash. The team’s design includes a hinge for angle adjustment, a series of panels for height adjustment based on the level of spinal cord injury, and an elastic strap to support the rider’s core.

Throughout the design, testing and manufacturing stages, the team learned the importance of putting the person with the disability at the center of the process.

Adaptive Sports Center Program Director Chris Read says this project has the potential to increase participation in their programs.

“Previously our participants didn’t have the best equipment options. These new designs will be very helpful,” he says.

Trade Fair judges were also impressed. Out of the 42 projects presented, the CSM FourCross team was awarded first place overall.

Safer Wheelchair Mobility

Senior Design team AdvantEdge, composed of Erika Blair ’14, Michaela Hammer ’14, Justin Loeffler, Julia Morin, Katherine Poffenbarger ’14, Kendrick Stalnaker ’14 and Kevin Tornes ’14, designed a wheelchair with extra sensors to allow the owner, a 13-year-old girl with cerebral palsy, to stop it before the system did, giving her more control.

Jered Dean ’04, MS ’09, associate teaching trofessor and director of the Engineering Design Program at Mines, took a personal interest in the work of Colorado AdvantEdge; as their client, he challenged the seven-member team to design a wheelchair sensor system that would detect drop-offs and prevent his niece, 13-year-old Katherine Dean, from driving over them. Katherine was born with cerebral palsy and uses a 286-pound electric wheelchair for mobility.

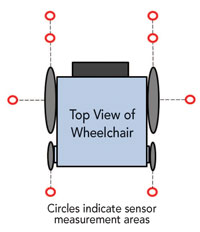

Assisted by advisor Yitz Finch and technical consultant Atef Elsherbeni, the Dobelman Distinguished Chair and professor of electrical engineering and computer science, the team designed a system that can detect a drop-off of three inches or more in a variety of light levels and ground compositions using eight distance sensors mounted on every side of the chair.

“Engineering decisions are often made solely with efficiency in mind,” says team member Justin Loeffler. “Our project allowed us to make decisions that would most benefit the user while still keeping efficiency in mind.” One of those decisions was adding extra sensors at extra cost,�to allow Katherine to stop her chair before the system did it for her, giving her more control and a feeling of independence. The work of the Colorado AdvantEdge team was recognized at the Trade Fair with the Kid’s Choice Award.