Within 15 years an army of robotic rovers could be roaming the red planet, scooping fine, sand-like topsoil (called regolith) and delivering it for processing into materials for human pioneers on Mars. Some regolith may be squeezed of its H2O to make fuel, propellant, and drinking water. Some may be made into bricks, sidewalk pavers, or radiation shields. The rovers are a critical piece of NASA’s plan to have humans on Mars by the 2030s. The more materials we mine there, the less we need to haul from Earth. But one nagging question exists: How will the rovers get around on a planet that has an ash-like surface, one-third the gravity of Earth, and a vacuous atmosphere?

(credit: Ozkan Celik)

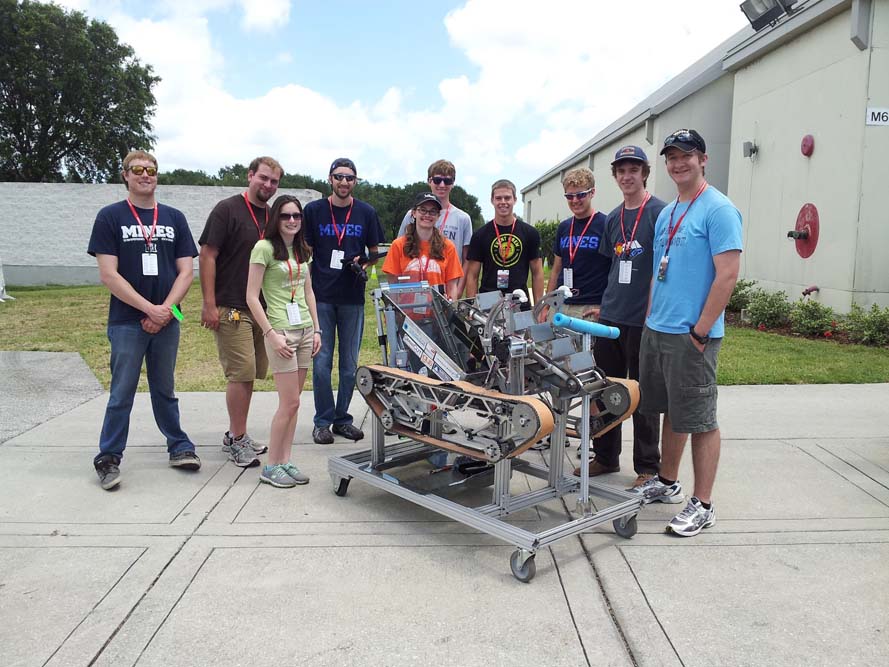

Enter Team Blasterbotica. Since 2008, teams of Mines students have attempted to build a Mars-worthy mining rover for their senior design project. They spend nine months designing, building, and testing it, then load it on a trailer and drive it to Florida for the NASA Robotic Mining Competition at Kennedy Space Center (KSC). There, NASA engineers look on as 46 teams navigate their creations around craters and scoop regolith at a simulated Martian mine.

“NASA is basically crowdsourcing ideas for robotic machinery that could someday mine materials on other planets,” explains faculty co-advisor Ozkan Celik, an assistant professor in mechanical engineering. “This is the frontier of human space exploration, and the students get to be a part of it.”

This year’s 14-member team built its rover ‘Jerry’ from scratch, with five different subgroups tackling drivetrain, excavation system, regolith delivery, sensing, and controls. Competition rules prohibit substances that ‘would not function in a Martian environment,’ which meant no wheels (they sink into the ash-like surface), no hydraulics (the fluid would evaporate in the vacuum of deep space), and no sensing equipment that could be impacted by dust (with little gravity to hold it down, it’s everywhere).

The team opted for a tank-like drivetrain made of chains, sprockets and tread, and a lightweight bucket ladder to scoop regolith. Then, they had to build it. “I am not the kind of engineer who grew up tinkering with stuff,” says team member Katie Kostecka ’15. “I learned a lot of basics, like how to bolt things together and use a grinder, from my teammates.”

At 10 a.m. on May 18, teammates stood sweltering in white protective suits (to protect them from floating particulates) in a KSC arena filled with ash. They looked on nervously as ‘Jerry’ weighed in. “It wasn’t allowed to weigh more than 80 kilograms, and it weighed in at 79.5,” says Kostecka.

(credit: Ozkan Celik)

On the first test run, a problem arose. The regolith was wetter than anticipated and gummed up the drive train, tearing off the chain. So, team members rushed out to buy some toothbrushes and bolted them to the sprockets to continuously wipe away regolith. “It worked remarkably well for something so MacGyver-ish,” Kostecka says.

On competition day the excavation system worked perfectly, but more problems hobbled the rover before it could deliver the 10 kilograms of regolith required to win a design prize. (Fewer than half of competing teams meet this requirement). Still, Kostecka sees the experience as a great success, she learned how to trouble-shoot on the fly.

The Mines team ranked 13th overall and 2nd in the Demonstration and Presentation category. “They knew what they were talking about in front of the judges, and they acted just as you would expect a professional engineering team to act,” says co-faculty advisor Christopher Dreyer, an assistant research professor in mechanical engineering.

For Kostecka, who grew up dreaming of a career in aerospace, the highlight was when a NASA engineer looked at their design, took notes, and spoke of ideas he has gotten from previous teams. “That made me feel like we are part of something bigger like there is a chance our work could someday have an impact,” she says. “It felt amazing.”