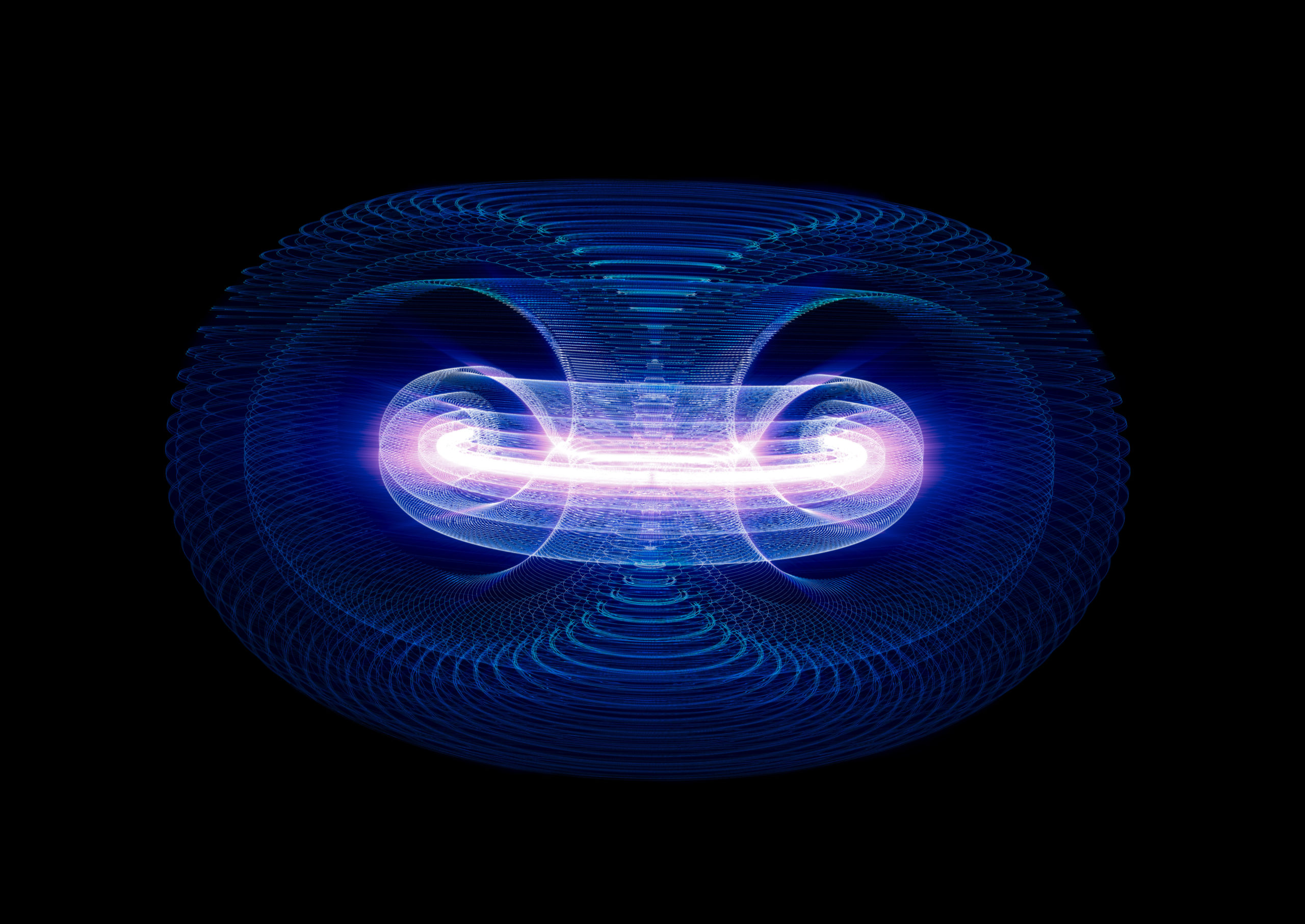

Fusion future

Fusion has the potential to be an unlimited carbon-free power supply, according to Colin Wolden, professor of chemical and biological engineering at Mines.

“Fusion is not unlike the processes that occur in the Sun—tritium and deuterium, isotopes of hydrogen, fuse together to create helium, which is accompanied by a very small loss of mass but an enormous release of energy in accordance with Einstein’s famous relation E = mc2,” he said. “This heat can be harnessed and used to run steam turbines in power plants instead of burning coal.”

But a critical challenge to implementing fusion power lies in the effective and safe management of tritium, a radioactive isotope with a short half-life. Wolden and Doug Way, professor emeritus of chemical and biological engineering, hope a composite metal membrane they developed for high-temperature hydrogen separations in conventional petrochemical refining operations could hold the key. These dense metal membranes purify hydrogen isotopes from impurities with perfect selectivity, critical for tritium-related applications.

The researchers are adapting the membrane technology to the unique constraints of the fusion environment with a goal of enabling lower cost and safer fusion energy systems by eliminating major fuel cycle components and reducing tritium inventory, release and required breeding ratios. The Fusion Safety Program at Idaho National Laboratory, including Mines alumnus Thomas Fuerst PhD ’18, will validate the membranes using the state-of-the-art facilities within its Safety and Tritium Applied Research (STAR) facility.

“At INL, we are investigating membrane technology to extract tritium from the breeder blanket as well as separate tritium directly from the reactor exhaust, which will provide improved efficiency and safety streamlining the current tritium fuel cycle,” Fuerst said. “We look forward to the collaboration with Mines as these advanced composite membranes may provide the answer.”