Extraction evolution

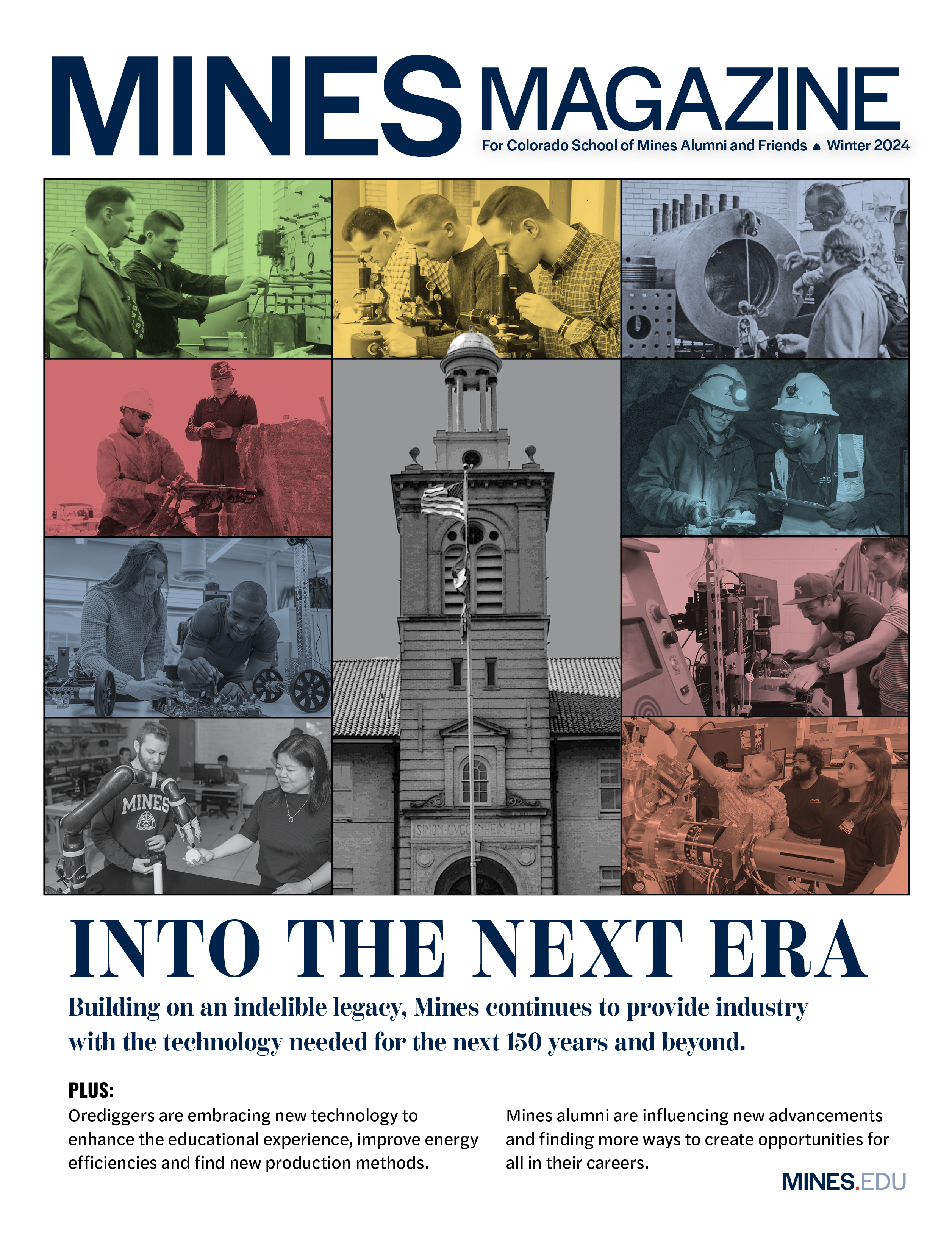

Since Mines was founded in 1874, technology has drastically changed, with new inventions propelling game-changing societal advances. These technological developments have altered the way humanity has interacted with the world and continue to influence modern research and learning experiences.

The mining industry is just one area that has seen a dramatic shift in technology in the past 150 years, with new enhancements allowing miners to work more quickly and safely. But long before computers, motorized vehicles or even electricity, the mining industry used comparably simple tools to extract valuable resources from the earth.

The tools shown here—a hand pick, assayer’s mold, candlesticks, blasting caps, drill bits, single-jack hammer and rock hammer—represent some of the more traditional technologies in use when Mines began educating students in the field. With these tools, many of the processes miners used to extract minerals and other resources from the earth were completed by hand, requiring extensive amounts of time and physical labor.

Over the years, many of these traditional mining tools have been updated or replaced, taking on modern designs and adapting to cutting-edge innovations. Now, drones can be operated for solo underground exploration or in tandem with other robots, advanced 3D subsurface models can help improve exploration success and minimize geologic risk and smart drills can provide information about a material to operators in real time to improve efficiencies.

These newer technologies have allowed the mining industry to grow exponentially and have shifted the way miners approach a worksite or determine what a particular mine has to offer. According to the Encyclopedia Britannica, “In modern mining, it is machines that provide the strength and trained miners who provide the brains needed to prevail in this highly competitive industry.”

Beyond industry, these technological advancements have also had implications in the classroom. Today’s students are no longer learning a singular field of study but required to take a more multidisciplinary approach to their education in order to be most attractive to employers and prepared to work with emerging innovations or new devices.

But these shifts in learning experiences and ever-evolving technology has proven one thing to be true: mining remains a critical field that requires new innovations to help improve processes and move the industry forward.

Various mine disasters in the early 1900s prompted the U.S. Congress to create the U.S. Bureau of Mines to help improve working conditions underground. Despite the prevalence of electricity in homes at the time, mines often remained in the dark due to the high cost of installing electric lighting underground, so in 1914, the Mine Safety Appliances Company (MSA) took the initiative to create a dependable and safe electric cap lamp.

MSA enlisted Thomas Edison to help design the Edison Cap Lamp, consisting of a battery worn on the miner’s belt. A flexible cord was attached to the cap lamp mounted on the front of a helmet, and the battery could power a six-candlepower lamp for 12 hours.

The hardhat shown here is likely from the 1980s or 1990s. Today’s headlamps are similar, cordless versions of this model.

Carbide lamps are powered by the reaction of calcium carbide with water, which produces acetylene gas and burns a clean white flame. Commercial production of carbide mining lamps began in the early 1900s, replacing the oil-wick lamp and candles as lighting in many mines. The lamp produced no carbon monoxide, consumed less oxygen and had a better light output. Small lamps, such as the one shown here, were attached to miners’ caps, while larger lamps were carried by hand or hung near a worksite.

However, the development of electric battery-powered lamps caused carbide mining lamps to soon fall out of favor, almost completely replacing carbide lamps by the 1930s.

The lamp shown here was most likely used in the 1930s.

This image shows a reflected light microscope that was used to examine opaque mineral specimens. A light is aimed through the horizontal tube on the scope, and an internal prism reflects the light down through the lens onto the sample sitting on the stage. The microscope has the ability to pass light both up and down—from prism down to sample and from sample up to the eyepiece.

The microscope in this photo likely dates back to the 1930s.

Technological time machine

A brief look back at some of the major innovations in the last 150 years.

In the past 150 years, humanity experienced one of the biggest booms in modern technology, with many inventions becoming the basis for technology in use today. In 1876, Alexander Graham Bell made the first phone call and Nikolaus Otto built the first internal-combustion engine. The first electric power plant opened in 1882, a radio transmission was sent across the Atlantic in 1901 and the first airplane took flight in 1903.

In the past 100 years, society took technology further with the first test flight of a liquid-fueled rocket in 1926, the first electronic television transmission in 1927 and the first electronic digital computer in 1937. Physicists produced the first self-sustaining chain reaction in 1942, and the first transistor was created in 1947, ushering in an era of inexpensive small electronic devices. In 1957, the Soviet Union kicked off the space race with the launch of Sputnik 1.

In the past 50 years, computers became small enough

for home use, and the basis of the internet was developed in 1974.

In the past 10 years, humans have made significant strides in artificial intelligence and machine learning, beginning with the program AlphaGo in 2017.