A New Layer to Metal Manufacturing: With the help of an ADAPT consortium, Mines is changing the history of manufacturing and entering the world of 3-D printing

Ask an expert about the possibilities that 3-D metal printing holds for the manufacturing industry, and chances are you’ll hear about GE Aviation’s fuel nozzle.

This important component of the CFM International LEAP engines that GE uses, which need to dispense precise amounts of liquid fuel, once required manufacturing and assembling 18 different parts. Now it’s just one piece, made with a laser that turns powder into solid metal, layer by layer, resulting in the desired shape. Not only does it save time and millions of dollars—the result is a component that’s 25 percent lighter and five times more durable than its conventionally manufactured predecessor.

But 3-D metal printing, also known as additive manufacturing, isn’t just for companies worth hundreds of billions of dollars. The field is so new, so wide open, that established companies are buying printers without fully knowing what they’ll use them for, and even start-ups operating out of garages are getting into the game.

Making sense of all this creative chaos is the mission of the Alliance for the Development of Additive Processing Technologies, or ADAPT, which officially launched at Colorado School of Mines in January 2016.

The people behind ADAPT are not shying away from high expectations.

“ADAPT is going to make Colorado the center of the universe for this knowledge, and we’re starting to see that already,” said Tom Bugnitz, executive director of the center and CEO of Manufacturer’s Edge, a nonprofit working to boost the competitiveness of the state’s 6,000 manufacturers through technical assistance and by fostering government and university partnerships.

“It will be iconic in changing the history of manufacturing,” said Heidi Hostetter, the vice president of Arvada-based Faustson Tool and chair of ADAPT’s Industry Board who led the effort to create the consortium. “In 20 years, people flipping through a book will see that a place called ADAPT helped change the face of manufacturing.”

Hostetter started the process that led to ADAPT three or four years ago. “It was the voice of the customer,” she said. “We deal with Ball Aerospace, Lockheed Martin—everybody was saying we need someone to champion this emerging technology. If we’re going to continue to grow as a contract manufacturer, we’ll have to figure this out.”

Bugnitz compares it to personal computers in the early 1980s. “Big businesses knew they had to watch it,” he said. Companies are investing in 3-D printing knowing they won’t turn a profit on it right away, Bugnitz said, “because if we don’t, we’re going to have our lunch eaten in five years.”

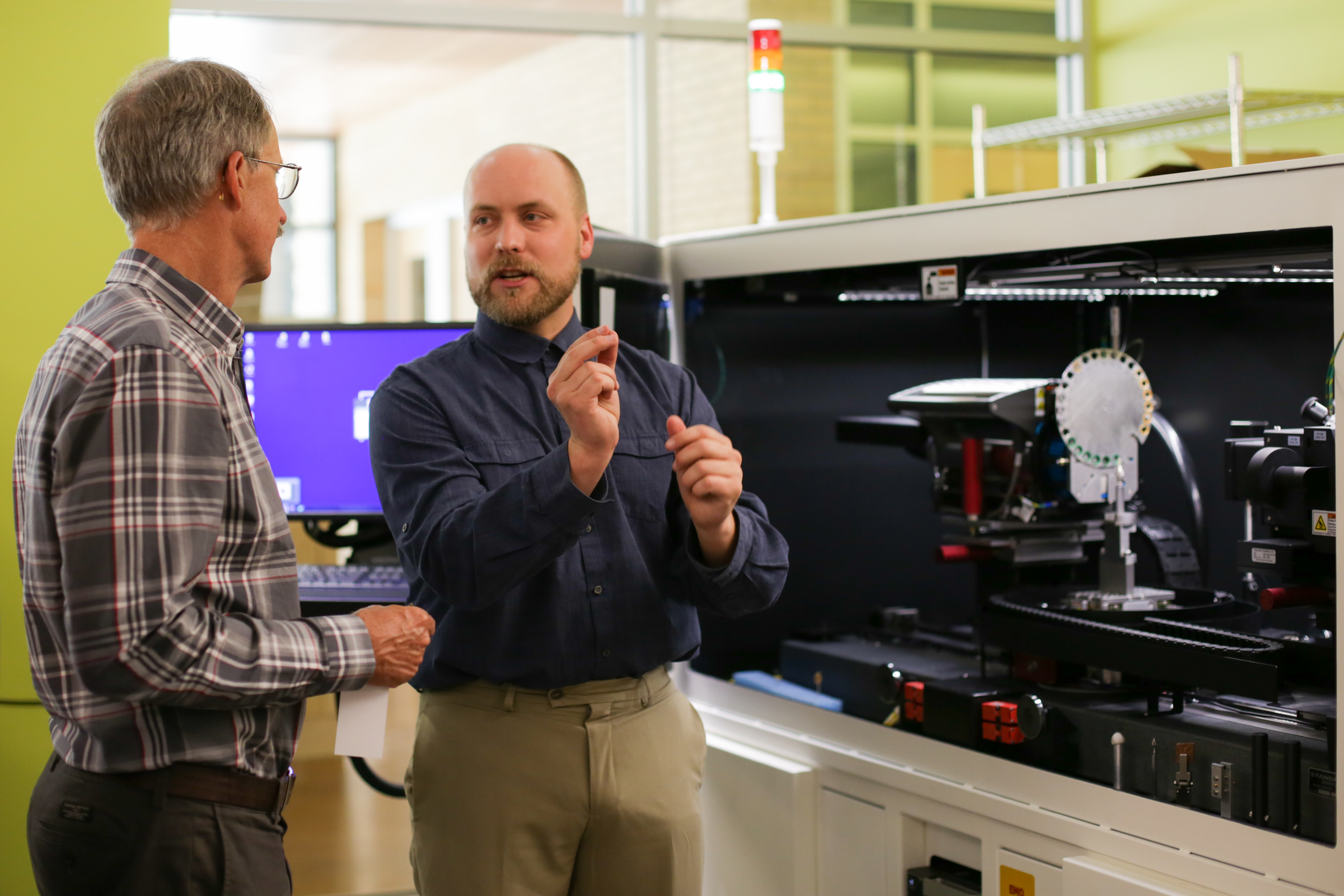

Hostetter and her fellow manufacturers identified the data analytics side of 3-D metal printing as a need nobody was filling, which is where Colorado School of Mines and a team led by Assistant Professor of Mechanical Engineering Aaron Stebner, ADAPT’s technical director, comes in.

Hostetter said successful previous collaborations with Mines professors led her to pitch ADAPT to Stebner. “What’s beautiful about Mines running it is that it’s just big enough and just personal enough,” she said. “The location is important, as well as the right team, and because of the size of the school, we’re more agile.”

“They have a very strong industrial perspective and recognize the unique needs of industry,” said Craig Brice, who works in Lockheed Martin’s Advanced Technology Center, within the Engineering and Technology organization.

“It’s a natural for Mines,” Bugnitz said. “Aaron is world-class, and Mines has a fantastic reputation in metallurgy, which is important. Mines has all of the things in place already: all the right people and all the right facilities.”

Stebner, who joined Mines in 2013, conducted postdoctoral research at the Graduate Aerospace Laboratories of the California Institute of Technology, where he specialized in the advanced characterization and modeling of the mechanics of metals. But he got his start in manufacturing as an intern for the Electric Device Corporation in Canfield, Ohio, eventually becoming responsible for the design and manufacture of automation solutions for assembling, testing and calibrating circuit breakers.

With personnel in place, founding stakeholders Ball, Faustson, Lockheed and Manufacturer’s Edge put up a combined $4.5 million toward ADAPT. The group successfully applied for a $2.5 million grant from the Colorado Office of Economic Development and International Trade, while Mines provided $1.2 million to outfit 2,200 square feet in the CoorsTek Center for Applied Science and Engineering, currently under construction and scheduled for completion in fall 2017.

ADAPT signed its contract with the state in January 2016 then moved into its temporary space in Brown Hall, holding an open house on June 23, 2016. Mines later welcomed Governor John Hickenlooper who was given a tour of the center on September 30 to kick off October as Manufacturing Month in Colorado.

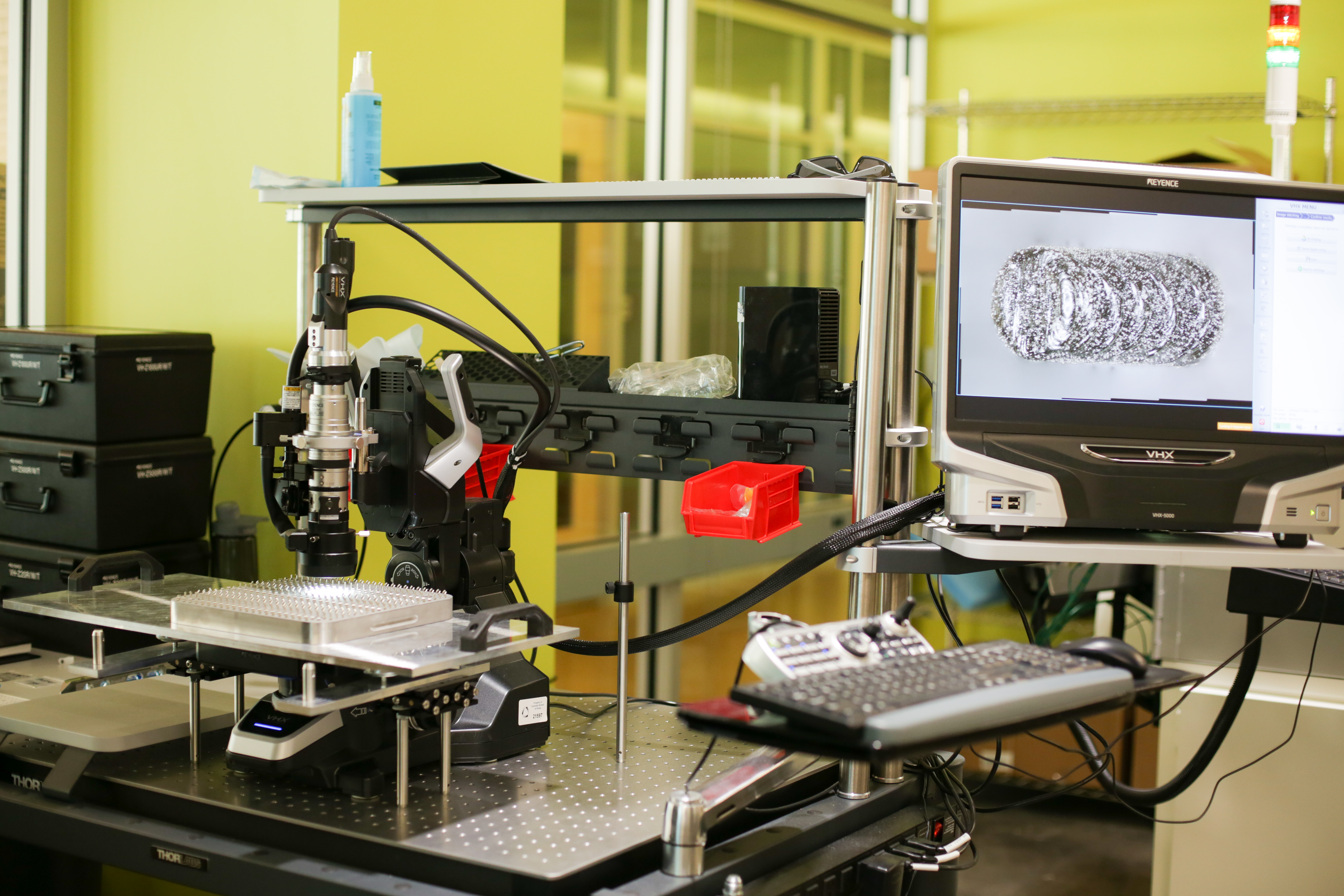

The consortium started with two fundamental research programs. One, for Faustson, essentially seeks to calibrate the company’s 3-D metal printer, which uses the same powder bed laser sintering method as GE’s. After many service calls for software updates for its machine, Faustson prints a test plate and sends it to ADAPT, which tests the samples for quality using incredibly advanced equipment, such as the first X-ray diffraction microscope owned by a U.S. university that’s capable of both diffraction contrast tomography and submicronresolution computed tomography.

“We’re characterizing their printer to help them know how to set their processing parameters for whatever part they’re trying to make,” Stebner said.

The second project involves refining the new method Lockheed Martin hopes to use to manufacture spheres to be used as rocket fuel containers for launching satellites. Right now, they’re made using solid blocks of titanium, 52 by 52 by 30 inches, which are machined out into extremely thin 48-inch hemispheres then welded together—a process that takes about 14 months.

In contrast, using a process that feeds titanium wires into an electron beam on a moving plate and creates a continuous meld in the desired spherical shape, plus the machining to smooth out the surface, takes about eight weeks. “That’s a game-changer to them,” Stebner said.

“Lockheed Martin has been an early pioneer with additive manufacturing,” said Brice. In the late 1990s, the then-president asked the research team to “pour me an airplane,” leading to one of the first industry labs focused on the technique.

Today, the company uses additive techniques to create prototypes, tooling and flight-ready parts, Brice said. One of the most recent uses was to create brackets the size of playing cards on the Juno spacecraft currently orbiting Jupiter. “This part flew 1,700,000,000 miles to reach Jupiter as of August 2016,” Brice said.

Other ADAPT projects include designing new alloys for biomedical applications and studying radiation damage in 3-D-printed materials for the NSA.

Individual projects aside, ADAPT’s main goal is to use data to solve problems in industry. And doing so requires compiling what Stebner calls “high-pedigree data.” “Everybody’s working on what’s the next material, what’s the next process, how do I make this part better, but nobody’s looking at data fundamentally as a way to qualify additive manufacturing parts,” said Stebner. “That’s where we’re focused. Different companies have different data problems, and we’re trying to set up a framework that can solve all of this.”

“Understanding this data problem is crucial for gaining confidence in the process and ultimately implementing additive manufacturing in production,” Brice said.

ADAPT can currently characterize about 4,000 parts per year; in two years, Stebner expects capacity to go up to 15,000 parts annually.

It’s about bridging the gap between academia and industry, said ADAPT Operations Manager Branden Kappes, a research assistant professor of mechanical engineering at Mines who oversees several undergraduate and graduate researchers as well as a postdoctoral fellow. “We’re transforming data from the lab into a format that industry can use in designing a new part.”

And it’s not just for members who have 3-D metal printers—at up to three-quarters of a million dollars, the cost is a pretty substantial barrier to entry—the data can be used by companies seeking consistency and quality in outsourced work.

The consortium has partnered with Citrine Informatics to use machine-learning techniques to create computer models that optimize the parameters for manufacturing a given part using a particular printer. These models are then made available to consortium members via a private database.

Since launching, ADAPT has added several members just through word of mouth, including Reaction Systems Inc., Qualtek Manufacturing Inc., Elementum 3D (formerly Sinter Print) and Confluent Medical Technologies.

ADAPT leaders expect to add more members in the coming year. Manufacturer’s Edge has been reaching out to economic development corporations as well as to manufacturers directly. “We’ve been getting a good reception,” Bugnitz said. “Companies are probably thinking about 3-D metal printing already, and they have the same questions we all have. It’s on everybody’s radar screen, even though it’s new.”

Kappes sees plenty of opportunity for growth in the industry. “It’s analogous to the App Store or Google Play, where individual developers can distribute a game,” he said. “3-D printing allows individuals to fill little niches, pivot to new parts, address changing customer demand.”

The ultimate promise of 3-D printing would be the flexibility to suddenly shift and build a general production part, to “build drone wings one day and widgets the next,” Kappes said. Printers could be networked and simply download new programs, similar to how viewers choose movies on Netflix.

Another frontier for 3-D metal printing is size—the ability to manufacture both larger parts and components as small as one micron, or one millionth of a meter.

Lockheed Martin envisions that a combination of traditional processes and 3-D printing will be the trend in the near future, with additive manufacturing used not just in the large space systems the company is known for but also for payloads and small satellites that augment their missions. “We’re looking forward to the day when we can transmit an entire design to an additive manufacturing machine and literally print a satellite and its sensors in one piece,” Brice said.

The possibilities extend beyond traditional manufacturing applications, as shown by Confluent Medical’s membership. The company established a postdoctoral fellowship with an initial $100,000 gift. “We’re developing partnerships with the University of Denver and their biomechanics department for building artificial implants, with the goal of building parts specific to the individual,” Kappes said. “In a futuristic view of this technology, you would go in and perform a CT scan of a patient’s hip and build a part that matches their physiology and anatomy.”

“The whole goal, from my perspective, is creating jobs, and we’re going to see that,” Bugnitz said. He expects machine shops and defense contractors to further adopt 3-D printing and hire more people, and he envisions companies involved in 3-D printing to cluster in Colorado—such as those that make the powders used in the process.

“Companies are going to come here,” Bugnitz said, “and companies that are already here are going to expand.”

Since this story was written, ADAPT was for contributing to the Golden’s economic vitality by the Jefferson County Economic Development Corporation. Read more here.

In March, astart-up specializing in larger and more complex 3-D metal printing became the newest member of ADAPT, to contribute to creating next-generation data informatics and advanced characterization techniques in this rapidly growing branch of manufacturing. Read the story here.

Trackbacks/Pingbacks