Taking note of the high-end protective clothing that motorcyclists and car racers wear at events, former Denver Nuggets dancer Kady Zinke was dismayed there wasn’t anything comparable for dancers.

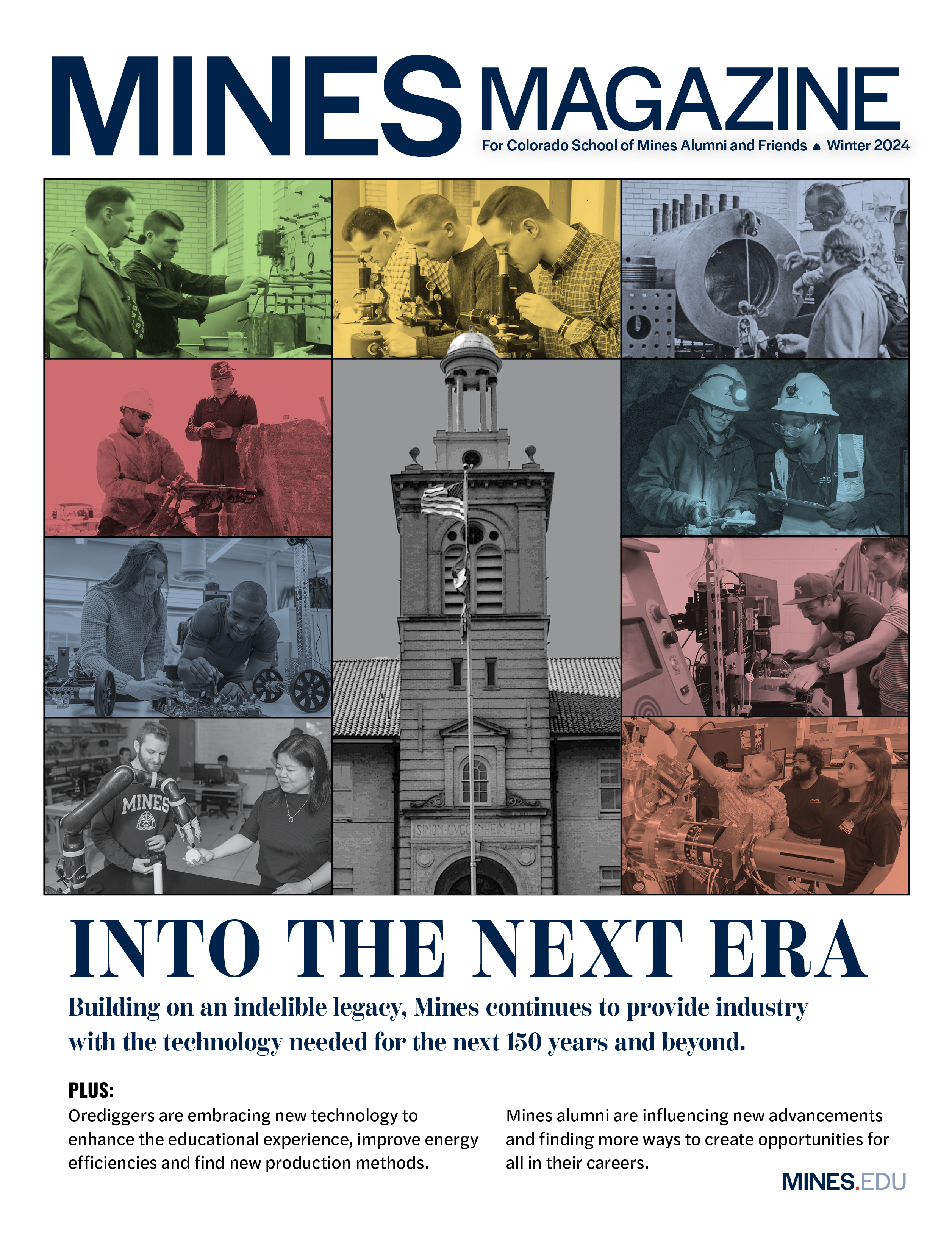

Terry Lowe (far right) oversees the Anti-Injury Activewear research team, who are all part of the Nano-Structured Materials Research Group.

Zinke, who founded her own activewear company, decided to take matters into her own hands. She reached out to Mines for engineering expertise and connected with Terry Lowe, a research professor in the George S. Ansell Metallurgical and Materials Engineering Department. They discussed the possibility of developing clothing that could help protect dancers from injury, specifically bruised knees. Knee injuries are among the most prevalent in dancers, and the protection that is offered currently tends to be ‘bulky, unattractive and constricting.’

Lowe wasn’t convinced he could offer a solution or find the financial support to pursue the project.

‘The constraints imposed by Kady were just too difficult: trying to put aesthetic, non-restricting, nearly invisible padding into dancer-style tights and still provide adequate protection,’ Lowe said.

After nearly giving up on Zinke’s concept, Lowe discovered a solution that could meet her requirements: crafting a new energy absorbing hybrid material system that combines shear-stiffening compounds (similar to cornstarch) and specially designed impact-lattices (that look like miniature bridge trusses).

‘If you have an impact in one spot, the rest of the pad can contribute to absorbing energy. A pressure wave from the impact goes out into the shear-thickening fluid and transforms it to absorb energy,’ Lowe said. ‘By adding in impact-lattices, you can design structures that absorb four or five times more energy than a typical foam.’

Incorporating the impact-lattices also helps the pads recover instantly from compression while keeping the same protection in place, which in turn reduces the trauma dancers experience from multiple falls.

In June, the duo received a $30,000 grant from the Colorado Advanced Industries Accelerator Program to fund the assessment of the best currently available padding materials, and then design, fabricate, and test their new high performance product, nicknamed ‘Dancy Pants.’

Over the summer, metallurgical and materials science student Michaela Rillings helped Lowe oversee the ‘Dancy Pants’ project team of six students (four from Mines, one from University of Colorado Boulder and one from Princeton University). This school year, they are augmenting the group with two engineering senior design teams that will work on a new project concept design and fabricate materials.

After the team tested competitor products for information on how to optimize the energy absorption properties of their prototype, they discovered that micro lattices performed three times better than most energy absorbing materials.

‘With these lattices, we can make it feel as soft as your cheek when you’re wearing it. This new design gave us something we wanted but we didn’t anticipate how much we could get with such control. It’s soft

at first but when it sustains impact, it’s stiff,’ Lowe said.

A competitive Irish step dancer, Rillings knows several people who have suffered impact injuries that have forced them to stop performing.

Currently, the team is testing how to customize the stiffness of the micro lattices so they could form to the body of each individual user. Their technology eventually could have many additional applications including other athletic gear, protective material for police and military personnel, and compact impact-tolerant packaging.