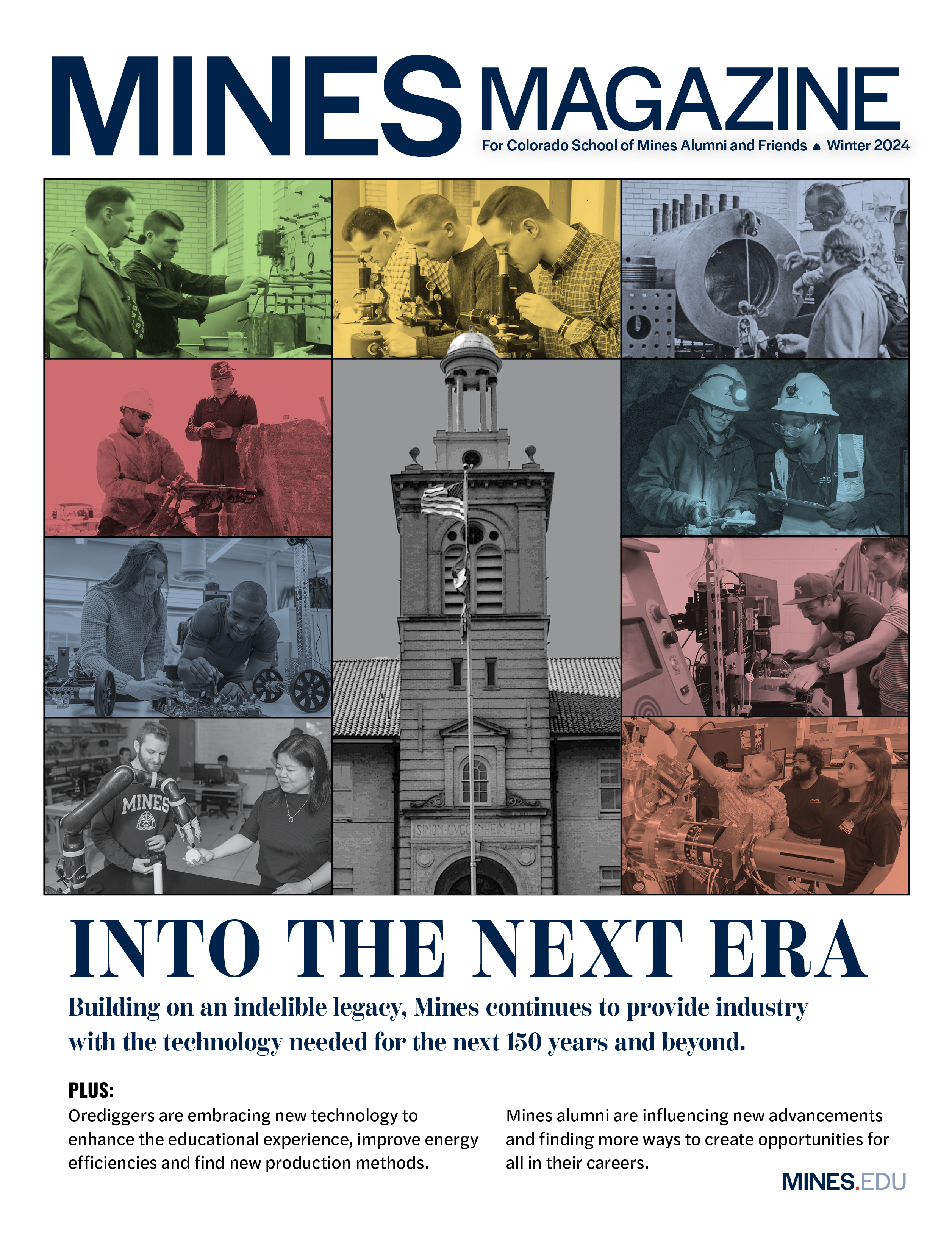

Amy Clarke is flanked by U.S. Secretary of Energy Steven Chu on the left and John Holdren, President Obama’s science and technology advisor and director of the White House Office of Science and Technology Policy. Clarke won a PECASE in 2012 for her work in metallic alloys.

In 2012, Amy Clarke MS ’02, PhD ’06 produced a metallurgical first: movies that show bulk metallic alloys in the process of crystallizing. It might not sound like blockbuster footage, but it helped earn her a trip to the White House and one of the nation’s top awards for young scientists, a Presidential Early Career Award for Scientists and Engineers (PECASE). Clarke is currently a research and development scientist at Los Alamos National Laboratory.

In addition to recognizing Clarke’s groundbreaking research on how the strength of a uranium-niobium alloy varies depending on the orientation of the crystalline structure, the award cites her work ‘using in-situ solidification and proton radiography with potential to finally resolve liquid-solid processing questions.’ Clarke explains, “We’re now able to see inside a material while it’s solidifying. We’re able to see the microstructure develop, which ultimately can tell us a lot about how processing parameters will influence properties; it has a lot of potential for industrially important materials.” Her work in this arena also earned Clarke a United States Department of Energy Office of Science Early Career Research Program Award in 2012.

Processing microstructure and property relationships in materials is an extension of Clarke’s investigations at Mines in the Advanced Steel Processing and Products Research Center, where the Michigan native helped pioneer new processing techniques in sheet steel.

“The physical metallurgy of steel has a lot of similarity to the physical metallurgy of uranium,” she says. “I was able to take my experience working with steel and apply it to uranium.”

Clarke began working with steel as an undergraduate at Michigan Technical University, where she graduated magna cum laude in 2000. She chose Mines for her graduate studies because the steel center was one of the few places in the country where she could counduct the type of research she wanted to pursue. Her Mines dissertation won the prestigious Willy Korf Award for Young Excellence in 2007.

“Amy is a natural collaborator, and has already established a strong track record,” says John Speer, a professor of metallurgical and materials engineering at Mines who served as Clarke’s dissertation advisor. “She’s enthusiastic, thoughtful, and not afraid to address new challenges in research.”

In addition to honoring her research skills, the PECASE award recognizes Clarke for mentoring future metallurgists. She remains active in the steel center (of which Los Alamos National Laboratory is a sponsor), traveling to Mines routinely to collaborate with graduate students.

“That’s something I truly appreciated about the steel center,” she says. “As a student, I had the unique opportunity to interact with scientists from industry and Los Alamos National Laboratory. I’ve been really lucky to collaborate with these individuals.”

Clarke is hardly through investigating steel: The next step, she says, is using feedback from real-time monitoring to make in-process parameter changes that modulate microstructure evolution to achieve a desired set of properties. Her PECASE, which comes with five years of funding, will help her continue this work. And she will almost certainly remain a familiar face at the steel center, mentoring students and continuing her collaborations.

“The steel center is one of a kind,” Clarke says. “It integrates academic, industry and lab activities in a way that no other center really does.”