Taking a breath

Early on in the COVID-19 pandemic, medical professionals in ICUs across the country faced a critical shortage of lifesaving ventilators. And it looked like there was no easy way to increase production.

Thomas Milner ’81, MS ’86, a former professor at the University of Texas at Austin, and his research team there came up with an idea for a “bridge ventilator” to help fill the demand for these lifesaving devices, but with an unusual twist—the machine includes a windshield wiper part.

We sat down with Milner to learn more about this ventilator and the laser-based research he’s currently working on at the University of California, Irvine’s Beckman Laser Institute.

What was a main consideration your team made when designing a new ventilator?

Thomas Milner: Many ventilators have a very minimal functionality. Ventilators fall into two classes—you have one class that doesn’t really listen to the patient or try to breathe with the patient, and then you have another class that tries to breathe with the patient, so it gives a breath when the patient says, “I need a breath.”

We made the decision pretty early on that we would not try to build one of the ventilators that doesn’t listen to the patient. We felt like if it’s going to really have much use, it’s going to have to be operable in what’s called a patient-assist mode. That required some fairly careful software development to learn how to sense or detect when the patient is trying to breathe.

Your team used a windshield wiper motor from a Toyota Camry to power a small caster wheel that automatically compresses the artificial medical breathing unit bag to control oxygen flow, eliminating the need for a person to manually compress the bag. What was the inspiration for using this mechanism?

Milner: We knew it had to be something that was readily available and can run and run without failing and was inexpensive. When you’re looking to manufacture something, you have to make sure there’s enough parts and inventory to meet however many you’re manufacturing. There’s a lot of motors that could be used, but they were generally a lot more expensive, and the inventories for them were much lower. There’s a variety of windshield wiper motors with large inventories and they’re very reliable—they last a long time—and the cost is low.

What other COVID-19 research are you working on?

Milner: The National Institutes of Health put out a call for a technique to be able to screen millions of people a day. Most of the existing approaches are chemical-based, but I started talking to some of my colleagues here at the Beckman Laser Institute and we started thinking about how we can detect the virus optically.

So a person would wear what we call a “smart mask” that essentially has a little harvesting patch embedded in it. The person would walk up to a kiosk, which would have to recognize the person, recognize some markings on the mask and then direct a laser beam to the site of the harvesting patch in the mask. And then by looking at the light that comes back from that harvesting patch, the discrimination of whether the virus is there—or not—can be made.

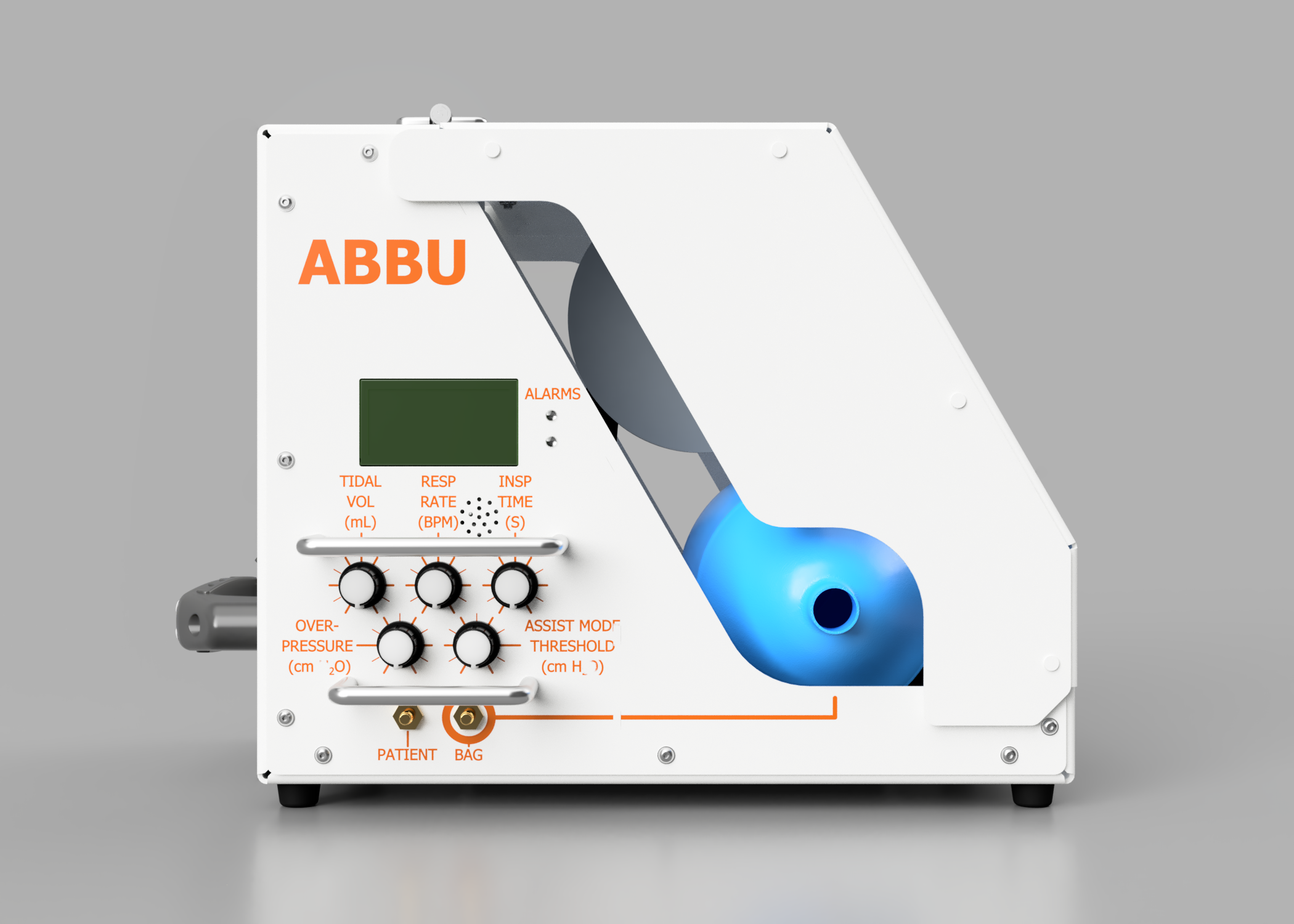

HOW THE BRIDGE VENTILATOR WORKS

Existing Assisted Bag Breathing Units use a manual resuscitator, called an artificial medical breathing unit bag. The bag is a handheld device that fills up with oxygen and a mask that patients wear to receive ventilation. But the unit requires a person to compress the bag frequently to

help patients breathe, presenting a problem when medical personnel are stretched thin.

The windshield wiper motor in the bridge ventilator allows the bag to compress automatically with four potentiometers to control the respiration rate, oxygen volume, time to inhale and maximum pressure.